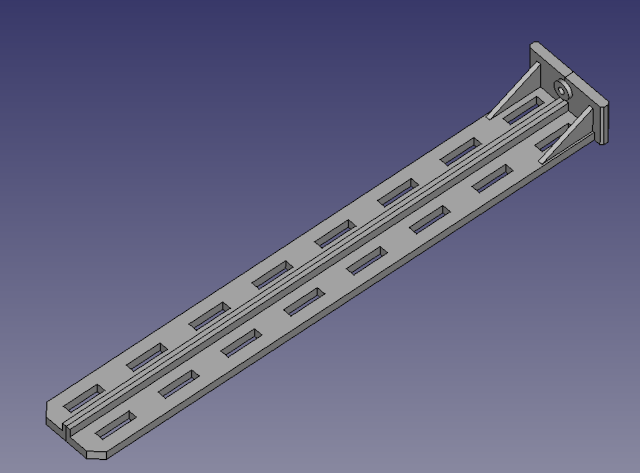

I'm attempting to print a part like this:

The part must be printed in the orientation shown due to the anisotropic properties of 3D printed parts: The part needs to be printed such that the print layers are oriented perpendicular to the expected load.

This wouldn't normally be an issue, but the part is 25cm long. The build volume of the Prusa i3 MK3S is 250 × 210 × 210 mm. That left me exactly one way to print the part: Lay it on the print bed lengthwise.

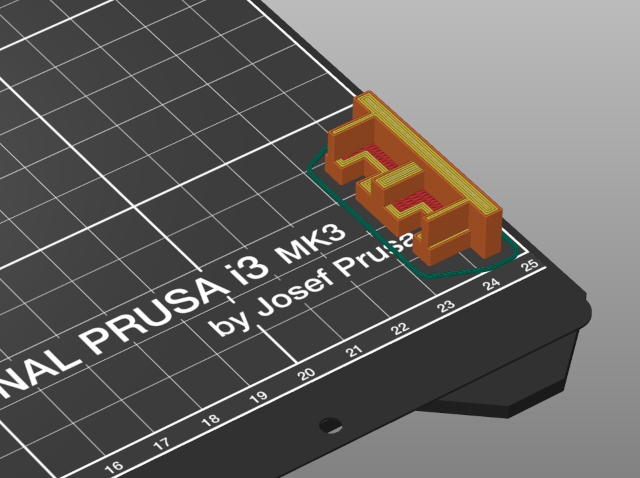

Because I wasn't completely certain that the part dimensions were correct, I printed a small slice of the end of the model for testing:

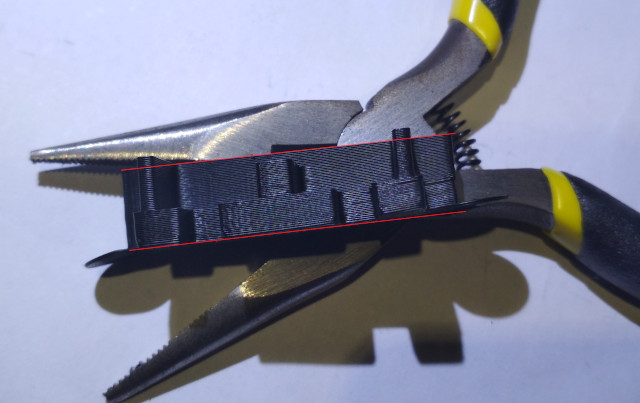

Unfortunately, the printed part was pretty severely warped. The two highlighted lines are supposed to be parallel!

The part was printed in eSun ABS. Now, ABS has the reputation of being difficult to print. It reportedly has a tendency to warp and shrink in exactly the manner shown above. However, my personal experience of ABS has been the complete opposite to date! I've not, so far, had a single part warp in any observable way. I think I've had good results so far due to printing exclusively in an enclosure, using a 110°C heated bed, and tuning the material settings carefully. Therefore, having a part come out of the enclosure looking like this was a bit of a surprise.

My first thought was to question where I was printing on the bed. I don't normally print in that lower right corner. I tried moving the slice of the model to the middle of the print bed and printing again... No warping!

Late last year, I attached a small PVC duct to the back of the enclosure so that I could vent ABS fumes out of the window during prints. Given that we're coming into the winter months in the UK, I wondered if the warping was actually caused by a cold draft from outside getting into the enclosure and ruining the first print. I moved the part back into the corner and printed again... It warped. Not only did it warp, but it suspiciously warped in exactly the same manner as the first print; one of the corners (not both) lifted from the heat bed. Coincidentally, the corner that lifted was the corner that was placed in the same location on the heat bed both times (the bottom right corner).

I tried printing a version of the part with "mouse ears" - small brims placed under each corner. Once again, the part warped, and specifically only warped on one corner. The entire brim on that corner of the part actually lifted off the heat bed, whilst the other corner stayed firmly down.

In the above image, the marked lines are supposed to be parallel. Severe warping and buckling can be observed on the right side of the part, and absolutely no warping is present on the left side. The part is symmetrical; if it warped on one side, it should warp on the other.

At this point, I was pretty much convinced that something was unusual about that specific part of the heat bed.

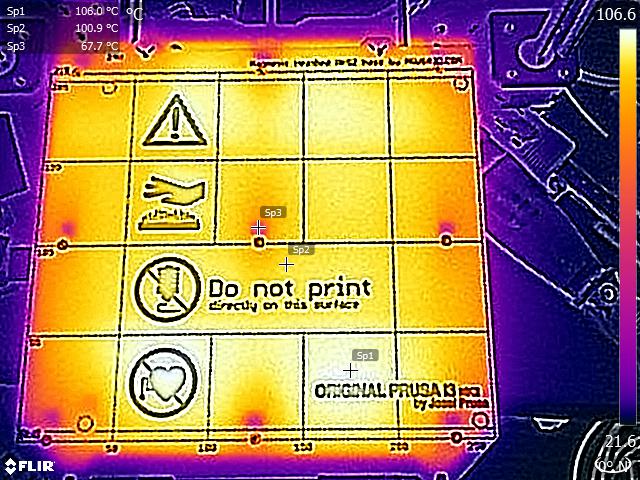

I found a discussion thread on the Prusa forums where someone had produced a thermal image of the heat bed running at temperatures very close to the temperatures I'm using for ABS:

The original poster notes:

Heat distribution is not perfectly even, but it doesn't look too bad. The cold spots are where the magnets sit.

...

These images are without a steel sheet attached. When a steel sheet is added, it should spread out the heat more evenly towards the perimeters of the bed.

Note that in the image, both the bottom left and bottom right areas of the heat bed are noticeably colder than the rest. This might not matter for larger parts, but for a part with a small corner area, it clearly does!

I suspect moving the part to the next grid square over (in the horizontal band that says "Do not print") will fix the problem.