Ordered and received some eSun ABS.

I must admit, I was expecting a fight. If you look on the internet regarding the printing of various filaments, you'll find page after page describing ABS warping, cracking, and otherwise being a nightmare to use. It's regarded as being one of the more difficult filaments to print. Given my recent experiences with Eryone PETG, and taking into account that PETG is supposed to be easy to print... I was expecting to have to expend a lot of effort getting reliable ABS prints.

The eSun ABS was nicely packaged. A rigid cardboard box, containing a vacuum-sealed spool accompanied with silica gel as a dessicant:

The spool wasn't tightly wound. I'm unsure if this is a problem or not.

I first printed a standard vase-mode cube

to check the extrusion multiplier. I measured the wall thicknesses as

0.5, 0.53, 0.55, 0.48 yielding an average thickness of 0.515. Given

the target thickness of 0.5, that's an extrusion multiplier of

0.5 / 0.515 ≈ 0.970873786407767.

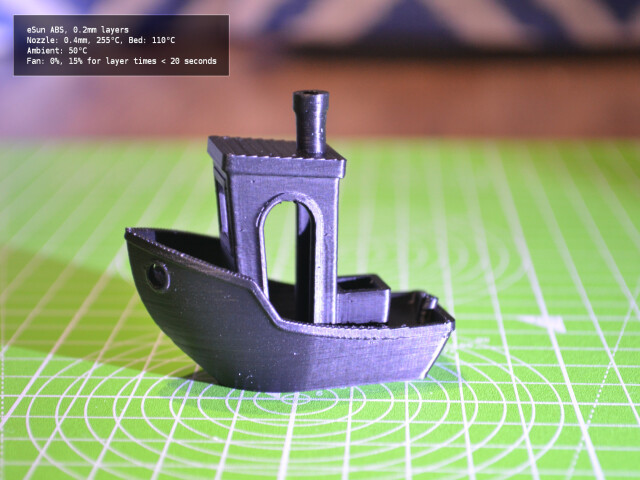

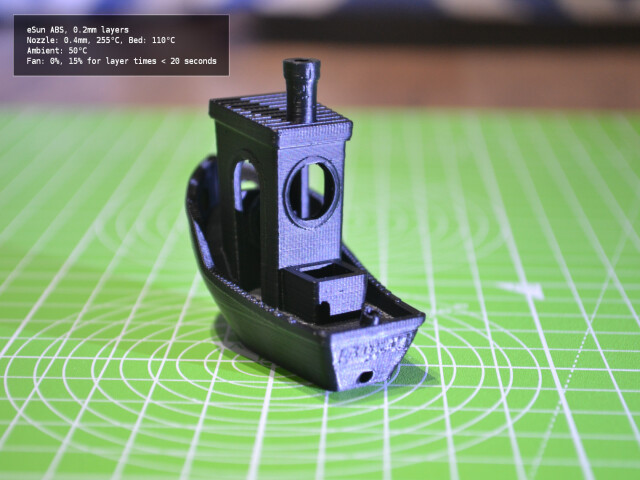

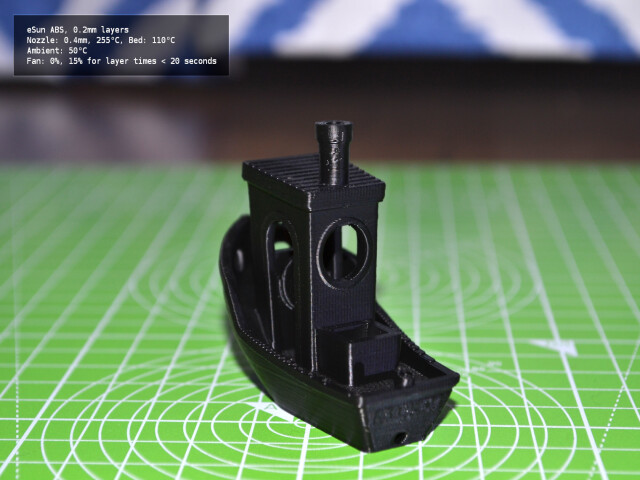

This time around, the Prusa slicer had a preset for eSun ABS. I took that preset as a base for the new ABS_eSun_2020-11-01 filament profile, adjusting the original for price and the extrusion multiplier. The filament cooling settings specify 15% fan for layers that are taking less than 20 seconds to print, but otherwise the fan is switched off. I did notice from playing around with extruding lengths of filament that ABS seems to cool and solidify much more quickly in the air than PETG or PLA. It also extrudes from the nozzle in a straight line downwards, whereas PETG almost immediately starts to curl.

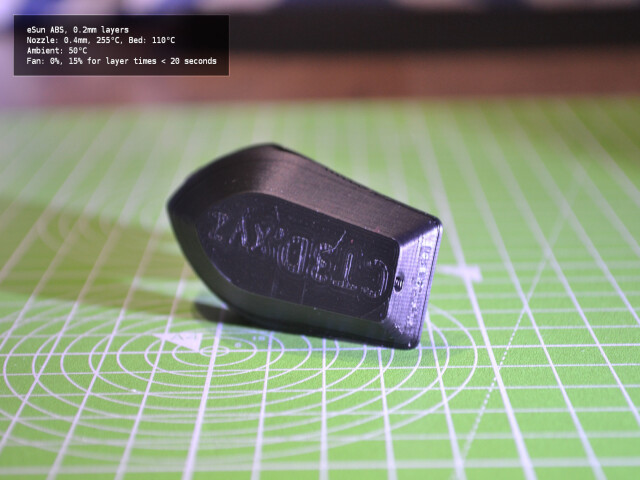

I assumed that the preset was at least vaguely correct, and leapt straight into a 3D Benchy. I didn't bother with a temperature tower, and decided that I'd only do that if the preset didn't work.

An hour and forty minutes later... I had a flawless Benchy. I've provided images in various lighting conditions to highlight the finish and layers.

I've not yet printed test rods to check the durability, but the print of the Benchy feels as tough as the PLA version. I'm unable to break anything on the print by hand. I printed directly onto a smooth PEI sheet, without any kind of release agent. I cleaned the PEI surface beforehand with isopropyl alcohol. My understanding is that while you need a release agent in order to get PETG prints off of the print bed after printing, with ABS you're typically fighting to keep the prints stuck down and therefore no release agent is necessary.

So... Somewhat anticlimactic overall. I was expecting resistance and didn't get any. I suspect my experience would have been different had I not been printing in an enclosure. I also didn't experience the clouds of toxic gas and aroma of melting Lego® bricks that I'd been told to expect. I suspect this was also down to the enclosure; perhaps most of the smell is particulate matter and is eliminated by the HEPA filter.