Success!

It seems that the issue was printing with a 0.3mm layer height. There's

simply not enough layer adhesion at that height to avoid brittle prints.

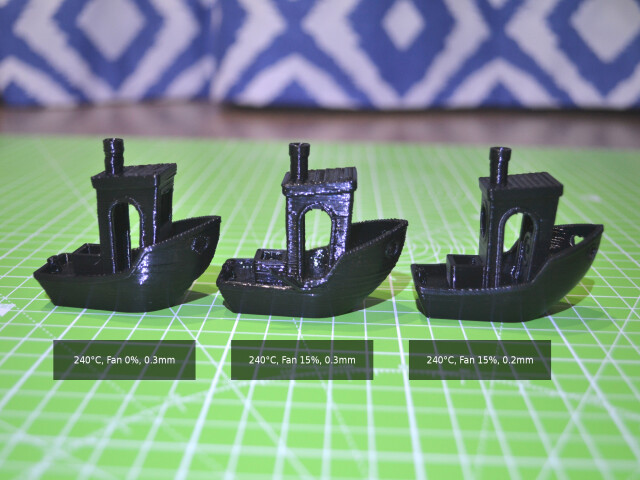

The left boat was printed at 240°C, with fans off, at 0.3mm layer height.

The print itself is strong, but the shape of the boat is slightly malformed

in general. Overhangs suffer, the bow of the ship sags, and the chimney appears

to be collapsing.

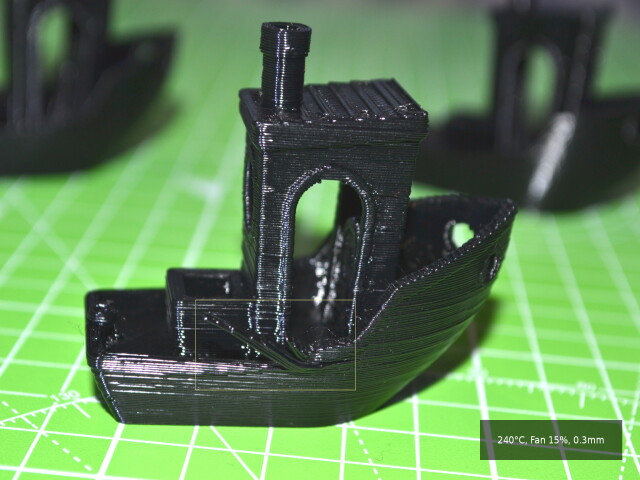

The middle boat was printed at 240°C, with 15% fans, at 0.3mm layer height.

The print looks better in terms of shape, but it's brittle. I was able to

damage the side railing by hand:

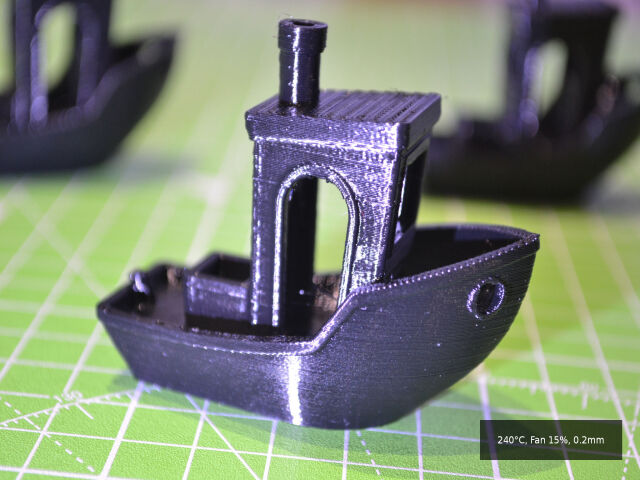

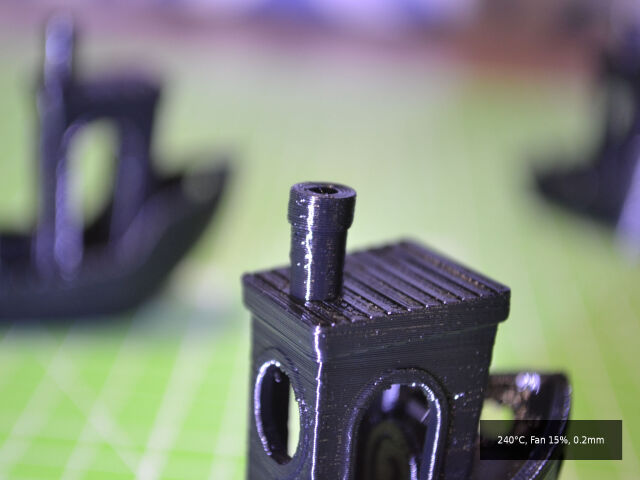

The right boat was printed at 240°C, with 15% fans, at 0.2mm layer height.

The result is pretty close to flawless. The details of the ship are clean,

there are no layer adhesion issues, and the shape is accurate:

For reference, here are the settings I used:

Ambient temperature: 50°C Nozzle type: Brass 0.4mm Layer height: 0.2mm Print base: Smooth PEI sheet with glue stick Very slow print rate: bridge_speed = 25 external_perimeter_speed = 25 first_layer_speed = 20 gap_fill_speed = 25 infill_speed = 25 max_print_speed = 25 max_print_speed = 25 max_volumetric_speed = 0 perimeter_speed = 25 small_perimeter_speed = 25 solid_infill_speed = 25 support_material_interface_speed = 100% support_material_speed = 25 top_solid_infill_speed = 25 travel_speed = 180 Infill overlap: 55% Infill: 15% cubic Extruder Temperature: 240°C all layers Bed Temperature: 85°C first layer, 90°C rest Perimeters: 3 Fans: 15%

This is the LH0.2_N0.4_PETGStrong print profile, using the PETG_Eryone_2020-10-26 filament profile, and the stock Prusa i3 MK3s printer profile.

The print took about 1 hour, 50 minutes.

What's interesting is that throughout all of the prints made, there has been almost no stringing. The camera tends to pick up any and all threads visible on the model even if those threads aren't visible to the naked eye. The only real threading/stringing was on the original temperature tower.

I'm satisfied that Eryone PETG is usable!