See Part 1 first!

I realized I never checked to see if the extruder was actually consuming

10mm of filament each time it asked for 10mm. In other words, I never

calibrated the extrusion multiplier

for the material.

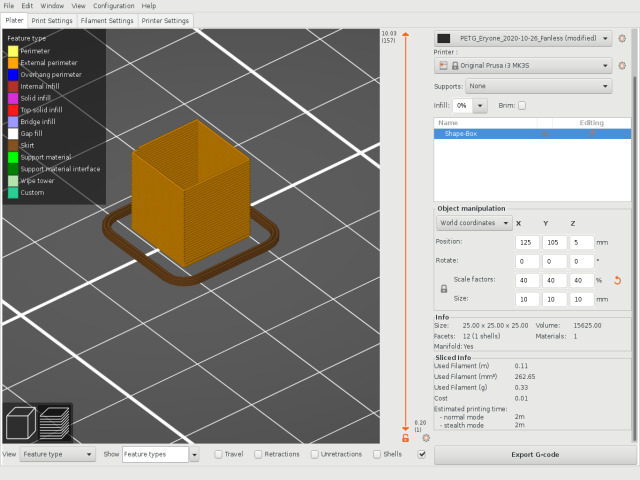

I printed a simple vase mode

box with a 0.5mm wall width, and the extrusion multiplier set to the default

value of 1:

I then measured the thicknesses of each wall of the resulting print with calipers. This gave me the following measurements:

0.52mm, 0.6mm, 0.52mm, 0.48mm

Averaging those numbers gave me 0.53mm. Dividing 0.53mm by the original

target width of 0.5mm gives 0.53 / 0.5 = 1.06. In other words, for every

unit of filament the extruder is trying to consume, it's actually pushing out

around 1.06 units. This is likely down to the compressive nature of PETG;

PETG is more elastic than PLA, and compresses when forced through an extruder.

Effectively, I'm slightly over-extruding. I then set the extrusion multiplier

to 0.5 / 0.53 ≈ 0.9433962264150942 and printed again. This time, measuring

the thickness of the walls gave me:

(0.52mm + 0.48mm + 0.5mm + 0.48mm) / 4 = 0.495mm

That is, the average thickness of the walls is off by 0.005mm, which is

likely within the margin of error for these digital calipers. Hopefully, this

should increase the quality of prints with the Eryone PETG as I continue to

try to determine the right settings for reliable, durable prints that don't

look like someone took a blowtorch to them.

Continued in Part 3...