For 3D printing, I want to print with more challenging materials than the standard PLA filament. Materials such as PETG benefit from the increased ambient temperature afforded by a enclosing a 3D printer in some sort of box, and materials such as ABS practically require it in order to prevent temperature-induced warping of objects during printing.

I wanted to build an enclosure myself, but unfortunately doing so would have really required printing parts in ABS for durability and temperature resistance. This introduced a bootstrapping problem; I'd need an enclosure to print the parts I'd need to build an enclosure. Rather than deal with the problem, I decided to just throw money at it instead.

I looked at the available enclosure kits, and Tukkari seemed to be the best option for the price. I wanted to buy the enclosure that supported the Prusa MMU2 as I'm intending to upgrade at a later date. Unfortunately, at the time that enclosure was out of stock. I emailed Tukkari to ask when the enclosure was coming back in stock, and it turned out that they were due in a few days. I kept an eye on the Tukkari web site but didn't see any change in the "in stock" status. I was about to give up and go elsewhere, but then I received an email from Jan Khynych at Tukkari mentioning that they'd had higher than usual demand for the enclosure, but that they'd kept one back for me in reserve! I was really impressed by this; they knew they would have sold them anyway, but they courteously kept one back for me in case I wanted it. Needless to say, I said yes, and the kit arrived by courier less than a week later.

The assembly process was easy. It arrived as a well-packaged flat pack. The first step was to attach the rubber feet and various pegs to the wooden base:

Apparently it's a kind of tradition to include regional sweets with these kits. The Prusa i3 kit included gummy bears.

The next step involved fitting the back board to the base, and installing the air filter. The air filter is a combined carbon filter and HEPA filter. This should make it more pleasant to be near the printer when printing with a material like ABS that produces styrene gas and particulate matter when melted. I'm intending to fit ducting to the back of the enclosure to vent that stuff out of the room.

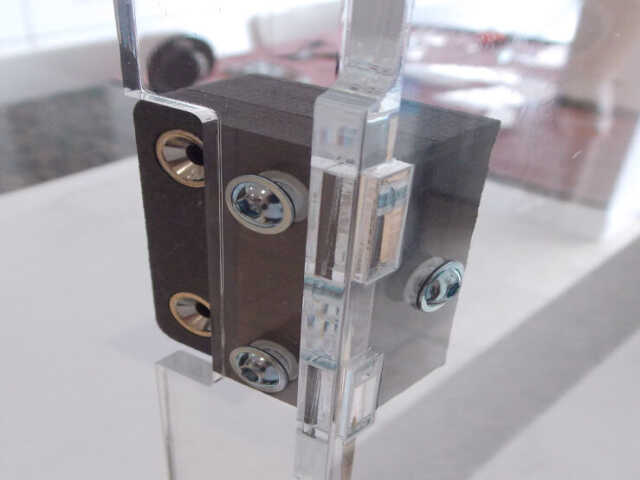

The door to the enclosure has a nice magnetic latch:

There's also a vent for the PSU:

I went with the spool holders that are designed to hold 2kg spools. I managed to screw this up, as I'll show later.

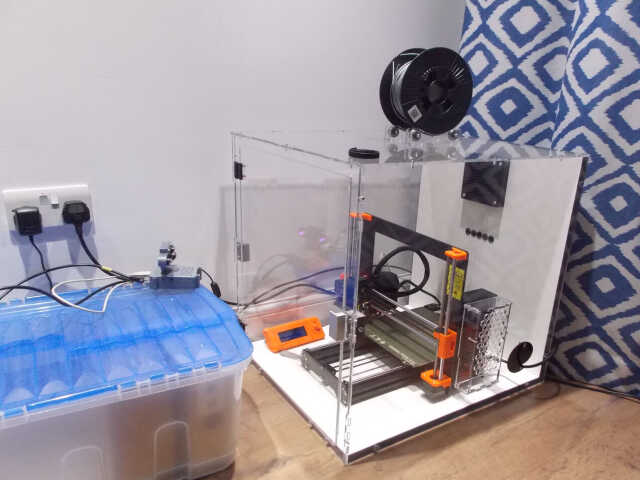

The final result:

So what I do think of the enclosure?

The good: The assembly was very easy. The packaging was excellent, with each individual piece of acrylic being packed in a protective film, and all parts protected from each other with polystyrene packing. The parts slot together very precisely, and the assembled enclosure feels rigid and sturdy. They included extra parts to fit a 120mm fan to the enclosure, and this allows for a slight negative air pressure inside the enclosure (which apparently is beneficial for reasons I don't fully understand) and also assists in getting ABS fumes out and away. The enclosure works as designed, and keeps a consistent ambient temperature during printing. I've not yet printed any ABS in it, but I've printed both PLA and PETG in it and have been unable to smell anything during prints. The PSU vent assists with keeping the PSU cool (the PSU is rated to operate in lower temperatures than the other electronic parts on the Prusa). I'd personally rather move the PSU outside of the enclosure entirely, but I can understand Tukkari not providing this as an option (it requires new cables for the printer).

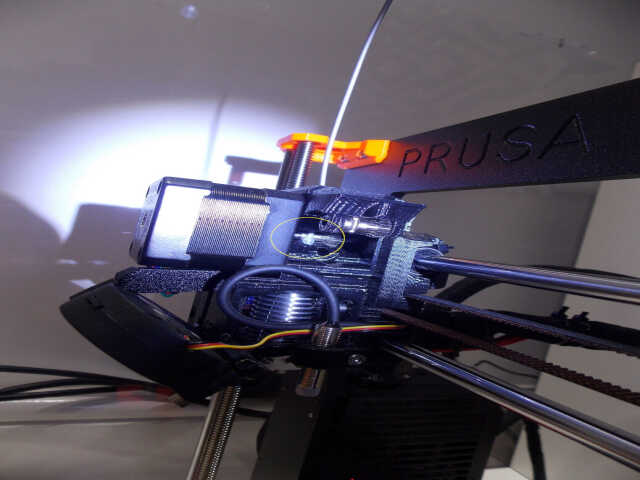

The neutral: I mentioned earlier that I screwed up the spool holders. What happened was that I failed to tighten one of the bolts on the spool holders, and during the first test print inside the enclosure, the filament spool worked itself into a gap between the bearings and the acrylic piece and got wedged in place. This meant that the printer could no longer pull filament from the spool, so the filament sat inside the extruder slowly melting. This ultimately resulted in a jam, which I further exacerbated by turning the printer off at the wall. This had the effect of cutting cooling to the extruder heatsink (because the fans switched off), and melting the filament inside the extruder to produce a nice immovable blob. I ended up having to disassemble the extruder to fix the jam...

Note that this is not the fault of the enclosure: I didn't assemble the filament spool holder correctly, and paid for my mistake. There was no damage to the printer or extruder. I'm not too fond of the spool holder design though. The other spool holder that Tukkari offer is fixed-width rather than being two pieces that can move independently. I think their fixed-width design is better and I probably should have chosen that one.

I have been warned against printing with PLA filament inside the enclosure; the higher ambient temperature can cause the temperature inside the extruder to exceed the glass transition point of PLA, and can cause the filament to melt before it enters the tube. Picture someone jamming bubble gum into a series of cogs, and you have a pretty accurate illustration of what can happen.

The bad: My criticism of the enclosure is really more philosophical than anything. The enclosure is presumably intended to be sold to DIY-level users rather than industrial-level users. People who are using DIY-level printers are very much the kind of people who are going to be endlessly modifying their printers and, by extension, their enclosures. The enclosure doesn't really offer any way to attach extra parts without actually permanently modifying the enclosure by drilling holes in it. Drilling holes in acrylic can be fraught with danger; it's pretty easy to crack acrylic and, once it cracks, it's more or less impossible to stop it cracking further. There are no threads on the sides of the enclosure where one could bolt a camera or lighting to help supervise prints. If you want to place the Prusa LCD outside of the enclosure, your only real option is to place it on top of the enclosure, and you need longer ribbon cables to do that (the cables supplied with the Prusa are just long enough to reach the front of the printer frame, and that's it). I'd like to see more options for extensibility in future revisions of this enclosure. I'm aware that there's a tension between adding extra holes and the like for extension, and keeping it actually functioning as an enclosure!

For now, I think I'm going to try to print off some brackets that I can bolt to the top of the enclosure (where the bolts pass through the top acrylic piece into the side acrylic pieces). This should hopefully allow me to bolt other things to the brackets such as the Raspberry Pi I currently have placed haphazardly on a box in front of the enclosure, and a separate USB webcam on a poseable arm. I've since replaced the provided spool holders with a dry box that sits on top of the enclosure.

Overall: The enclosure is pretty good. I'll be using it for the forseeable future!